Same Flight. Any Hardware.

Static calibration and simulation give your drone stable, predictable behavior — no matter the hardware.

Static calibration and simulation give your drone stable, predictable behavior — no matter the hardware.

When the mission matters, there’s no time for trial-and-error. Drones are field-assembled, loaded with one-off payloads, and deployed fast. Just one mounting change can throw off flight behavior and cause crashes. Today, tuning requires flight testing. That means time, space, and risk. In tactical scenarios, you don’t have any to spare.

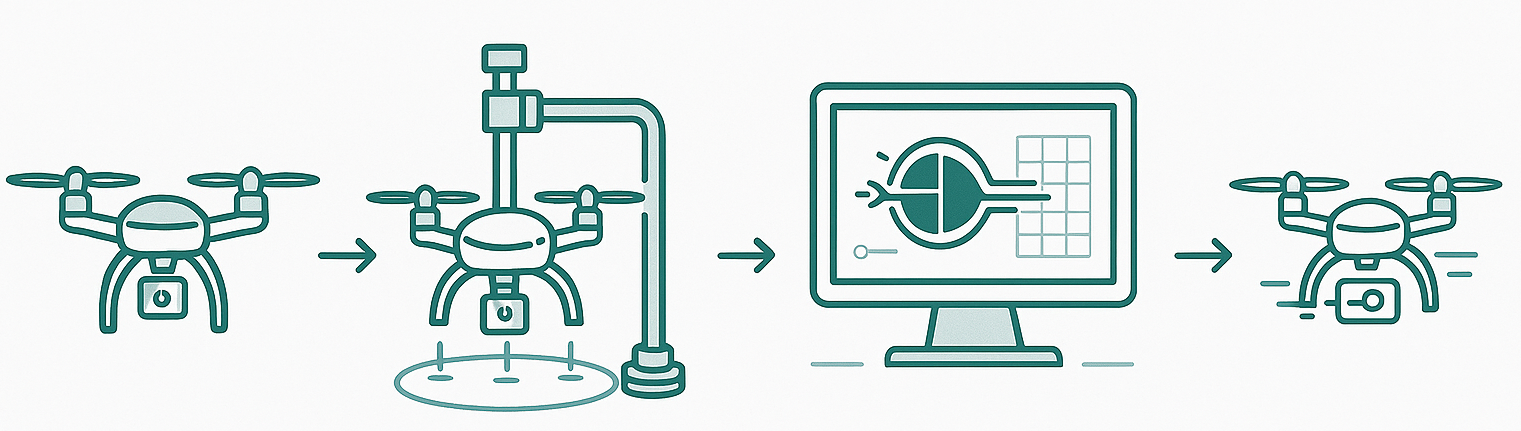

We replace flight-based tuning with static calibration and simulation. Our rig and software extract a drone’s physical and dynamic traits without flying. These parameters feed our simulator, which we use to configure a controller that wraps around the drone’s internal control stack and makes the drone fly like a known baseline. Regardless of payload or hardware, the result is predictable, repeatable flight performance. This decouples hardware and software, so teams can evolve each independently — and trust it all works in the field.

We’re focused on drones because the need is urgent. In field conditions, drones are often built quickly, loaded unevenly, and launched without time for flight tests, leading to unpredictable behavior and crash risks. By making drone behavior consistent, even across hardware variants, we help teams move faster, reduce crashes, and enable dynamic autonomy.

But the opportunity extends beyond drones. By standardizing the physical behavior of robotic platforms, we can decouple hardware from autonomy, so each can be developed independently, yet work together by default. As robotics scales, we aim to be the connective layer that lets hardware-software systems integrate seamlessly, even when built by separate teams.